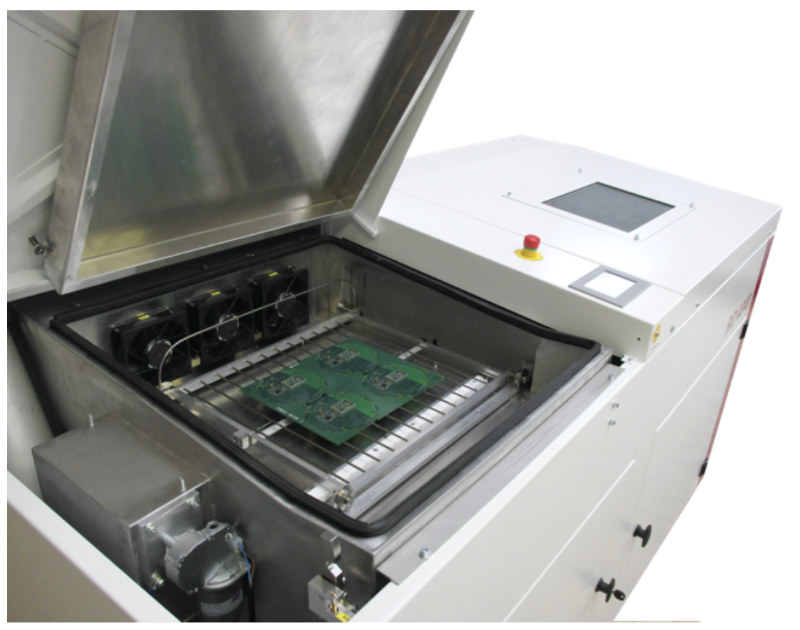

RD4040 Reflow Vapor Phase System

The RD4040 convinces by the modern and compact design, combined with established and reliable technology. The machine offers a large working area within a compact footprint. Features include automatic soldering control via a user friendly, color touch screen interface.

The compact and valuable 2-chamber design offers optimal accesibility and lowest possible process fluid consumption.

The product handling takes place through an aluminum work piece carrier, which offers a grid-type support for the printec circuit boards or soldering applications. Optional there is an adapter with lanes (rail-type support) for placement of double sided boards available.

The fluid monitoring and filtering system supplements the RD4040 to a reliable production machine, which finds its field of application in soldering and production of small and mid series ranges.

+ Only 2-3kWh power consumption during production

+ Oxygen-free soldering without Nitrogen

Standard equipment / features:

- HMI touch screen

- Sensor controlled solder automatic

- Modern heat-level regulation

- Program storage

- Level 3 password protection

- 2-chamber design

- Medium recovery

- Energy management system

- Integrated cooling station for board cooling

- Observation window to process chamber

- Prepared for connecting a extraction-system

- Automatic fluid level monitoring through fluid auxiliary tank

Options:

- Adapter for work piece carrier for soldering of double sided circuit boards

- Small meshed grid for the work piece carrier

- Cooling device, air-cooled water re-cooling system

- VP measurement system to record PCB thermal profiles, wireless system with 6 channels

- Exhaust fan

- Butterfly valve for the exhaust system

Benefits

Good accesibility

Comfortable loading and unloading area